Inventory management is a very complex task for companies with more number of products. With the increase in the number of products, complexity increases. Nowadays modern software keeps the records neat with the help of SKUs (Stock Keeping Units). Which is helpful in dealing with online market places as well. Managing inventory is very crucial in online business. Going out of stock at good causes significant loss and also impacts long term business. Similarly having too much stock at bad times also makes a lot of challenges. The key for a successful business model is a correct plan according to the market demand. Online business is not that hard, all one need to do is buy in bulk quantity and sell in small or single pieces online.

A lot of sellers in Amazon or eBay think about selling rather focusing on reordering or managing inventory. But the question is when exactly one must reorder to protect inventory from going out of stock or vice verse. Let’s look at the important factors which affect inventory and hence the business.

Demand Forecasting

Analysing the demand in the market gives a clear picture of the required number of units. Are the product you are selling is trendy? If so, it is better to have an inventory with full stocks. Since the trendy items sell quickly. If you have historical data on sales, which is very useful in forecasting sales. Forecasting data points such as demand, previous sales data, seasons and competitors must be included. Holiday seasons will increase sales, however, which is directly related to the type of product. Demand forecasting can be judgements which are based on previous experience. People with good experience in marketing or sales can tell how much they can sell. However, which is not true in many cases. Experience can be converted into a statistical model and one can get the logical explanation and better forecast.

Analysing the demand in the market gives a clear picture of the required number of units. Are the product you are selling is trendy? If so, it is better to have an inventory with full stocks. Since the trendy items sell quickly. If you have historical data on sales, which is very useful in forecasting sales. Forecasting data points such as demand, previous sales data, seasons and competitors must be included. Holiday seasons will increase sales, however, which is directly related to the type of product. Demand forecasting can be judgements which are based on previous experience. People with good experience in marketing or sales can tell how much they can sell. However, which is not true in many cases. Experience can be converted into a statistical model and one can get the logical explanation and better forecast.

Supply Chain Management tool helps in forecasting demand using mathematical based algorithms. The algorithm leverages modern technology like Deep Learning and Big Data to predict the possible outcome. Also recommends how much quantity needed to meet the forecasted demand. Having too much inventory causes maintenance problem which increases the cost. The inventory sitting in the warehouse is simply might cost an opportunity as well. The products will cover more space, which is a problem for other fast-moving items. Product degradation and quality reduction is another parameter one must consider while holding inventory. Under or Over Stocking causes financial burdens and it is bad for business.

Minimum Stock Level

Setting up the minimum stock level helps in balancing the gap or overlap between under and overstocking. Demand forecast helps in identifying these level and helps to keep the flow in inventory uninterrupted. If inventory goes below the minimum level, a re-order can be set up automatically with the help of software and reduce manual monitoring which saves in time.

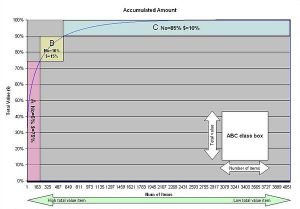

ABC Analysis

ABC analysis is inventory category technique in which the warehouse is categorised into A, B and C level. A is allowed for important products or high value in the warehouse. B is allowed for items which are less important than A and C is for small value items. A is composed of small quantity and on the other hand, C will be of a larger quantity. ABC model is very simple and can be adopted in any size of the warehouse. A similar approach can be used to categorise customers with respect to sales data and annual revenue. The model is very useful for online sellers since it connects the relationship between warehouse and customers with sales data.

ABC analysis is inventory category technique in which the warehouse is categorised into A, B and C level. A is allowed for important products or high value in the warehouse. B is allowed for items which are less important than A and C is for small value items. A is composed of small quantity and on the other hand, C will be of a larger quantity. ABC model is very simple and can be adopted in any size of the warehouse. A similar approach can be used to categorise customers with respect to sales data and annual revenue. The model is very useful for online sellers since it connects the relationship between warehouse and customers with sales data.

Finally, Inventory management is simple for small sellers however the complexity increases with the size of the order. Online sellers must give high importance reduce to maintenance cost and to keep the circulation of products in inventory effectively. Identifying the reorder point is the key to managing inventory successfully. There are many software out there which helps in forecasting demand, inventory management, reorder, reduce human error and the listing process can be made easy. Software or cloud-based inventory management tool helps in centralising inventory management. Always have a contingency plan when things didn’t go as planned. Manufacturer discontinues, wrong calculation of inventory numbers, sale spike, no space in the warehouse and much more unplanned conditions might arrive. Keep the stock-flow in control which will lead to great ROI.